|

|

Anode Quantities & Placement

When determining the cathodic protection requirements for your vessel the main factor to consider is the type hull material on the vessel and type of water.

How many anodes do I need?

| Steel Hull | GRP |

When determining the cathodic protection requirements for a steel hulled vessel the first criterion is the surface area of steel hull below the water line - the wetted surface area.

This is calculated by multiplying the water line length by the sum of the beam and draft i.e. LWL x (Beam+Draft). This calculation will apply to most motor cruisers and sailing boats.

Once the wetted surface area is calculated, it can be applied to the selection tables below from which the number of anodes required can be taken.

This is calculated by multiplying the water line length by the sum of the beam and draft i.e. LWL x (Beam+Draft). This calculation will apply to most motor cruisers and sailing boats.

Once the wetted surface area is calculated, it can be applied to the selection tables below from which the number of anodes required can be taken.

| Salt Water | Brackish Water | Fresh Water |

For one year in Salt Water fit the following Zinc anodes:

| Area | Hull | Anodes per Rudder | |

|---|---|---|---|

| Up to 28m2 | Stud Fixed | 2 x ZD78B | 2 x ZD56 |

| (300ft2) | Welded | 2 x ZD78 | 2 x ZD76 |

| 28.1 - 56m2 | Stud Fixed | 4 x ZD78B | 2 x ZD56 |

| (300 - 600ft2) | Welded | 4 x ZD78 | 2 x ZD76 |

| 56.1 - 84m2 | Stud Fixed | 6 x ZD78B | 2 x ZD56 |

| (600 - 900ft2) | Welded | 6 x ZD78 | 2 x ZD76 |

| 84.1 - 102m2 | Stud Fixed | 4 x ZD72BM | 2 x ZD58 |

| (900 - 1100ft2) | Welded | 4 x ZD80 | 2 x ZD77 |

| 102 - 148m2 | Stud Fixed | 6 x ZD72BM | 2 x ZD58 |

| (1100 - 1600ft2) | Welded | 6 x ZD80 | 2 x ZD77 |

For two years in Salt Water fit the following Zinc anodes:

| Area | Hull | Anodes per Rudder | |

|---|---|---|---|

| Up to 28m2 | Stud Fixed | 4 x ZD78B | 2 x ZD58 |

| (300ft2) | Welded | 4 x ZD78 | 2 x ZD77 |

| 28.1 - 56m2 | Stud Fixed | 8 x ZD78B | 2 x ZD58 |

| (300 - 600ft2) | Welded | 4 x ZD78 | 2 x ZD77 |

| 56.1 - 84m2 | Stud Fixed | 4 x ZD72B | 2 x ZD58 |

| (600 - 900ft2) | Welded | 6 x ZD73 | 2 x ZD77 |

| 84.1 - 102m2 | Stud Fixed | 6 x ZD72B | 2 x ZD78B |

| (900 - 1100ft2) | Welded | 6 x ZD73 | 2 x ZD78 |

| 102 - 148m2 | Stud Fixed | 8 x ZD72BM | 2 x ZD78B |

| (1100 - 1600ft2) | Welded | 8 x ZD73 | 2 x ZD78 |

For one year in Salt or Brackish Water fit the following Aluminium anodes:

| Area | Hull | Anodes per Rudder | |

|---|---|---|---|

| Up to 28m2 | Stud Fixed | 2 x AD78B | 2 x AD56 |

| (300ft2) | Welded | 2 x AD78 | 2 x AD76 |

| 28.1 - 56m2 | Stud Fixed | 4 x AD78B | 2 x AD56 |

| (300 - 600ft2) | Welded | 4 x AD78 | 2 x AD76 |

| 56.1 - 84m2 | Stud Fixed | 6 x AD78B | 2 x AD56 |

| (600 - 900ft2) | Welded | 6 x AD78 | 2 x AD76 |

For two years in Salt or Brackish Water fit the following Aluminium anodes:

For two years in Fresh Water fit the following Magnesium anodes:

To determine the number and size of anodes required, match the type of vessel and select the anode suitable for the size of propeller and the type of water.

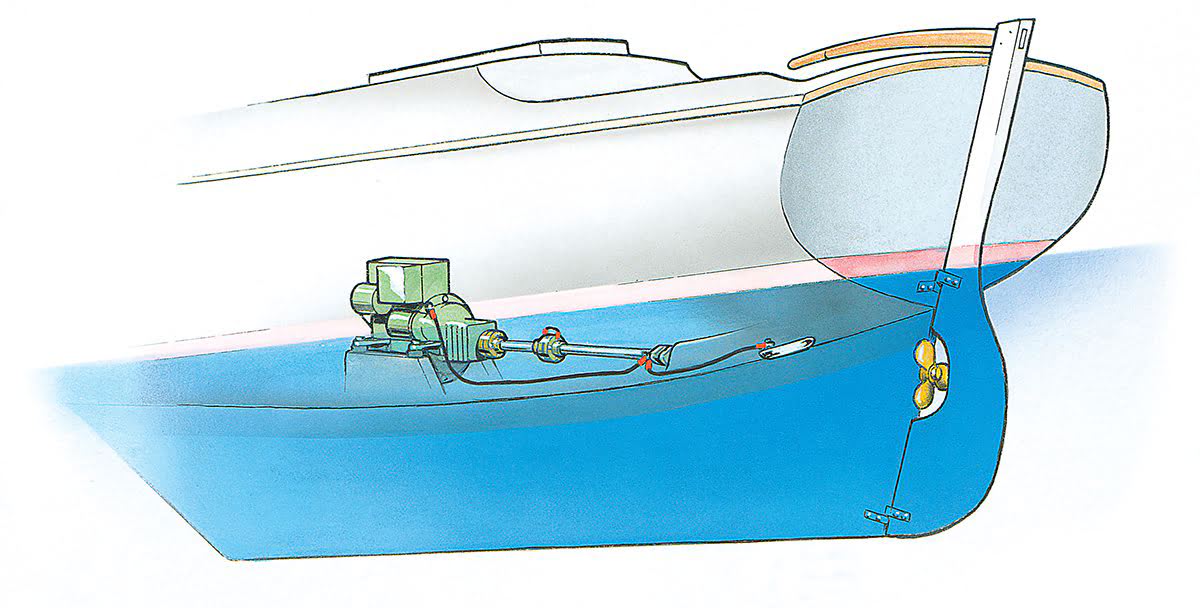

TYPE A Vessels are single screwed with a very short length of propeller shaft exposed to the water and fitted with GRP or wooden rudders. One anode will be required to protect the propeller and shaft.

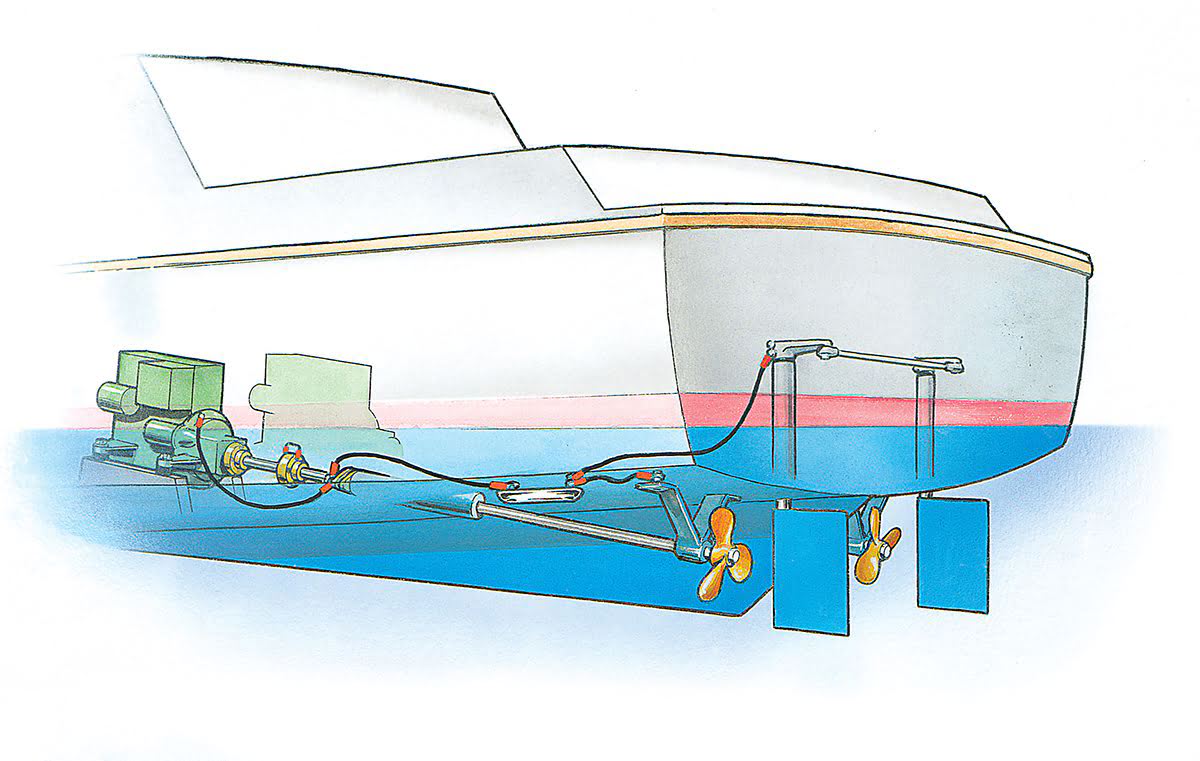

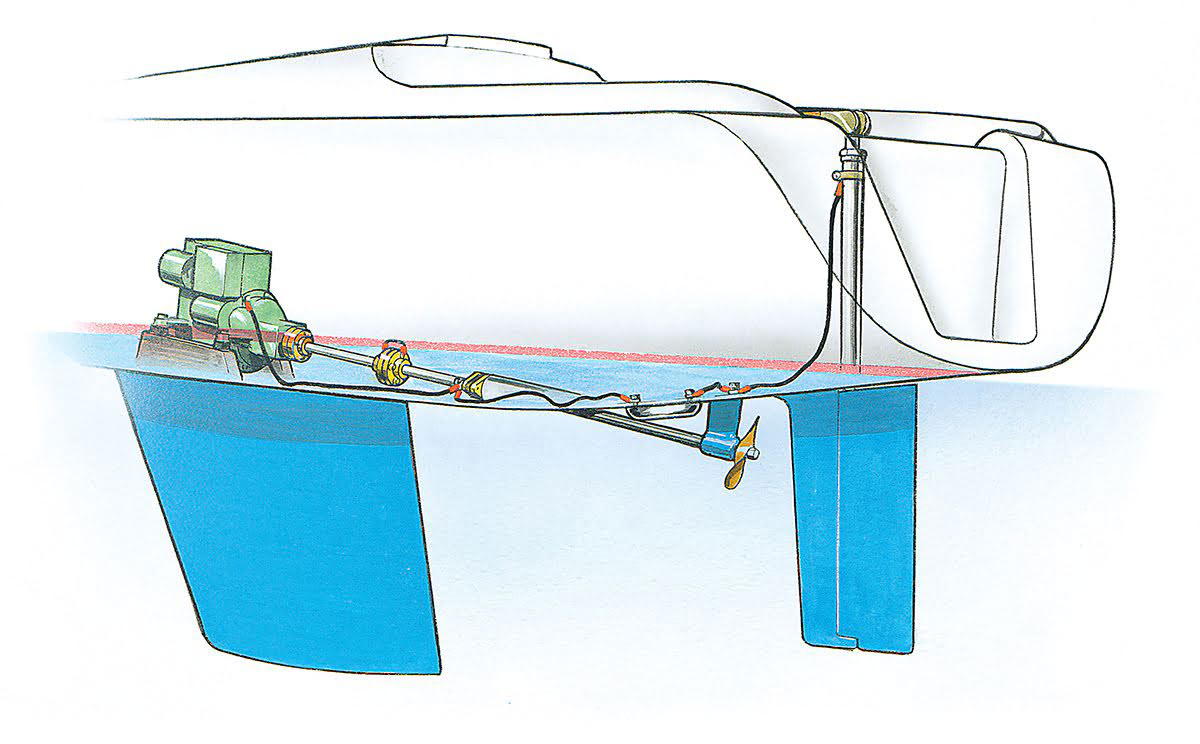

TYPE B Vessels are single or twin screwed with a long length of propeller shaft exposed to the water supported by a shaft bracket.

One anode will be required to protect each shaft assembly. Bronze or stainless steel rudders or GRP rudders with bronze or stainless steel stocks should also be bonded to the same anode, however mild steel rudders will require separate anodes.

TYPE C Vessels are single screwed with a long length of propeller shaft exposed to the water supported by a shaft bracket and GRP rudders with bronze or stainless steel stocks. One anode will be required to protect the propeller, shaft and rudders.

TYPE A, B or C - FOR EACH PROPELLER ASSEMBLY FIT ONE

| Propeller Diameter | In Salt Water | In Salt or Brackish Water | In Fresh Water |

|---|---|---|---|

| 250mm |

ZD56

Zinc Anode |

AD56

Aluminium Anode |

MD56

Magnesium Anode |

| 500mm |

ZD77

Zinc Anode |

AD77

Aluminium Anode |

MD77

Magnesium Anode |

| 750mm |

ZD78B

Zinc Anode |

AD78B

Aluminium Anode |

MD78B

Magnesium Anode |

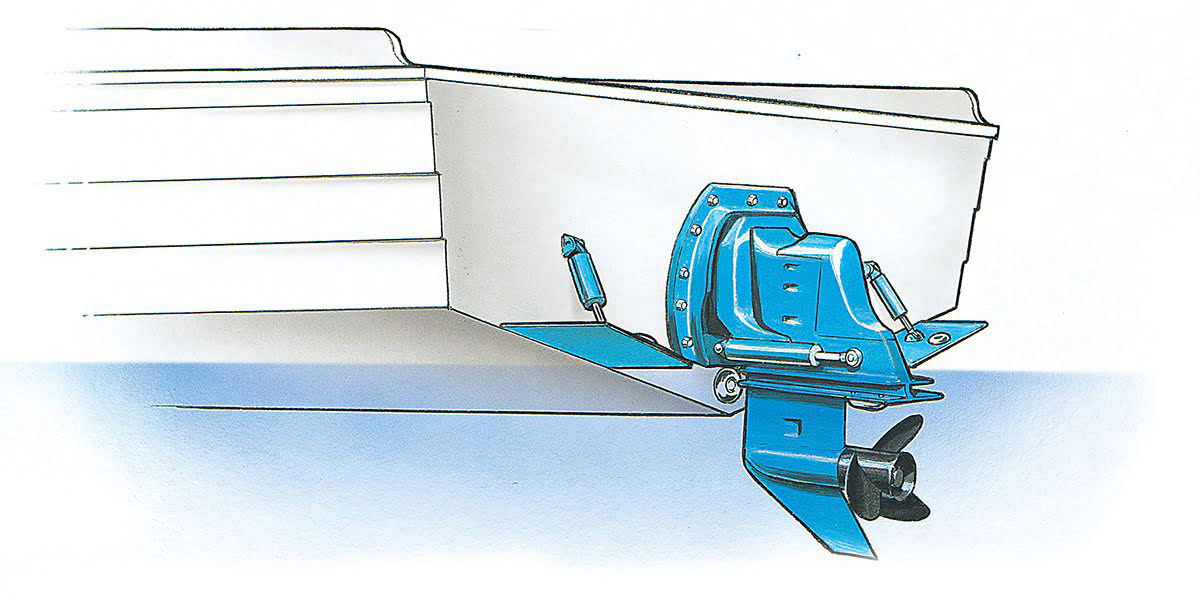

TYPE D Vessels are those fitted with saildrives, sterndrives or outboard motors. Most are fitted with sacrificial anodes specifically designed for them, and MGDuff replacements may be found on pages 22-29. We recommend regular visual inspection of outboards and sterndrives when moored, at least every 2-3 months, as the wear rate of the anodes can be affected by a variety of factors:

- The degree of tilt of the drive – anodes must be fully immersed

- Substitution of aluminium propellers by stainless steel versions

- Addition of stainless steel accessories such as propeller guards

- Loss of electrical continuity – many sterndrives have small continuity wires fitted between the component parts which must be replaced if broken, and stainless steel clips on rubber gaiters can loosen through pitting corrosion

Saildrive anodes too can be affected by bronze propellers and stainless steel rope cutters.

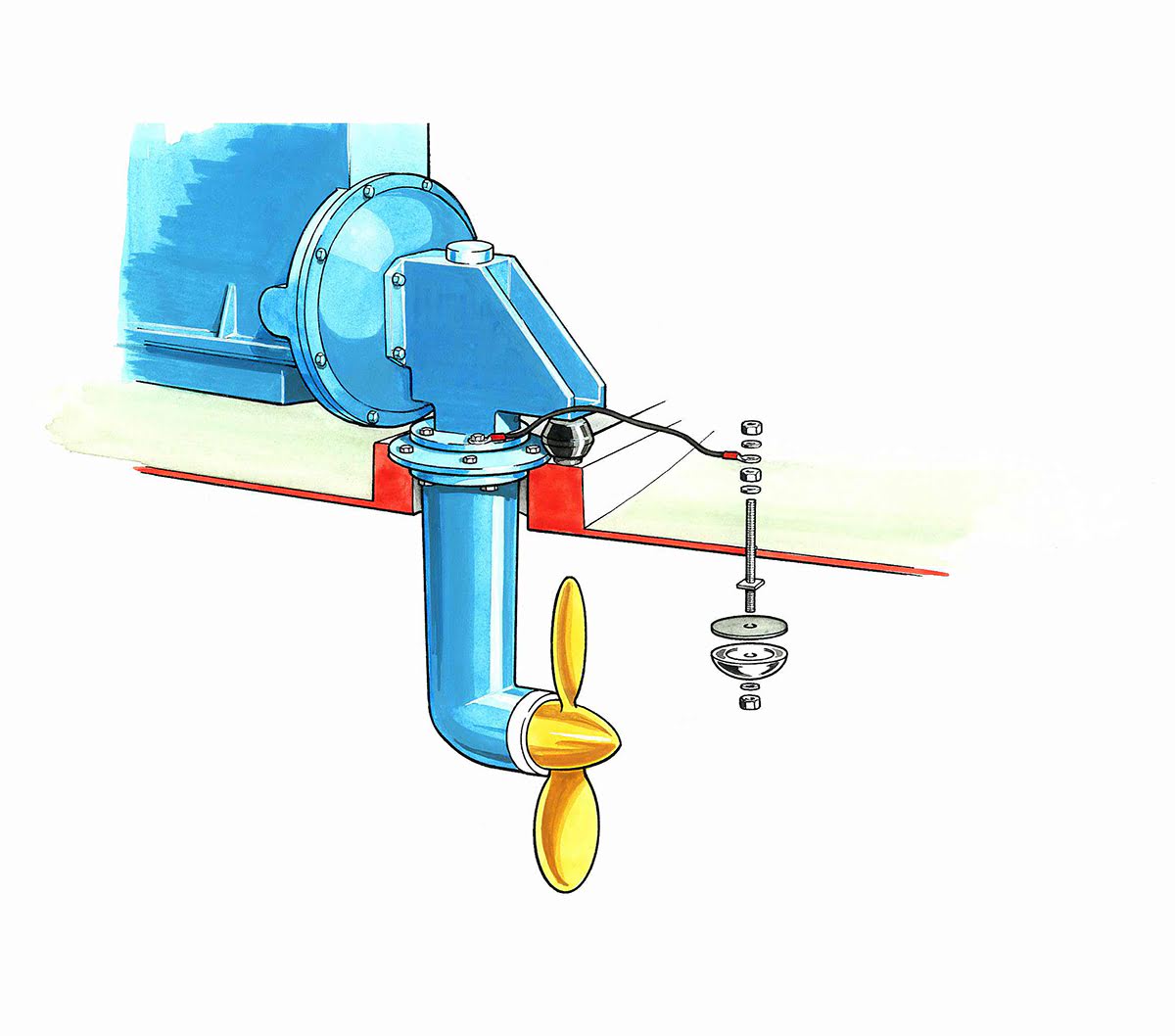

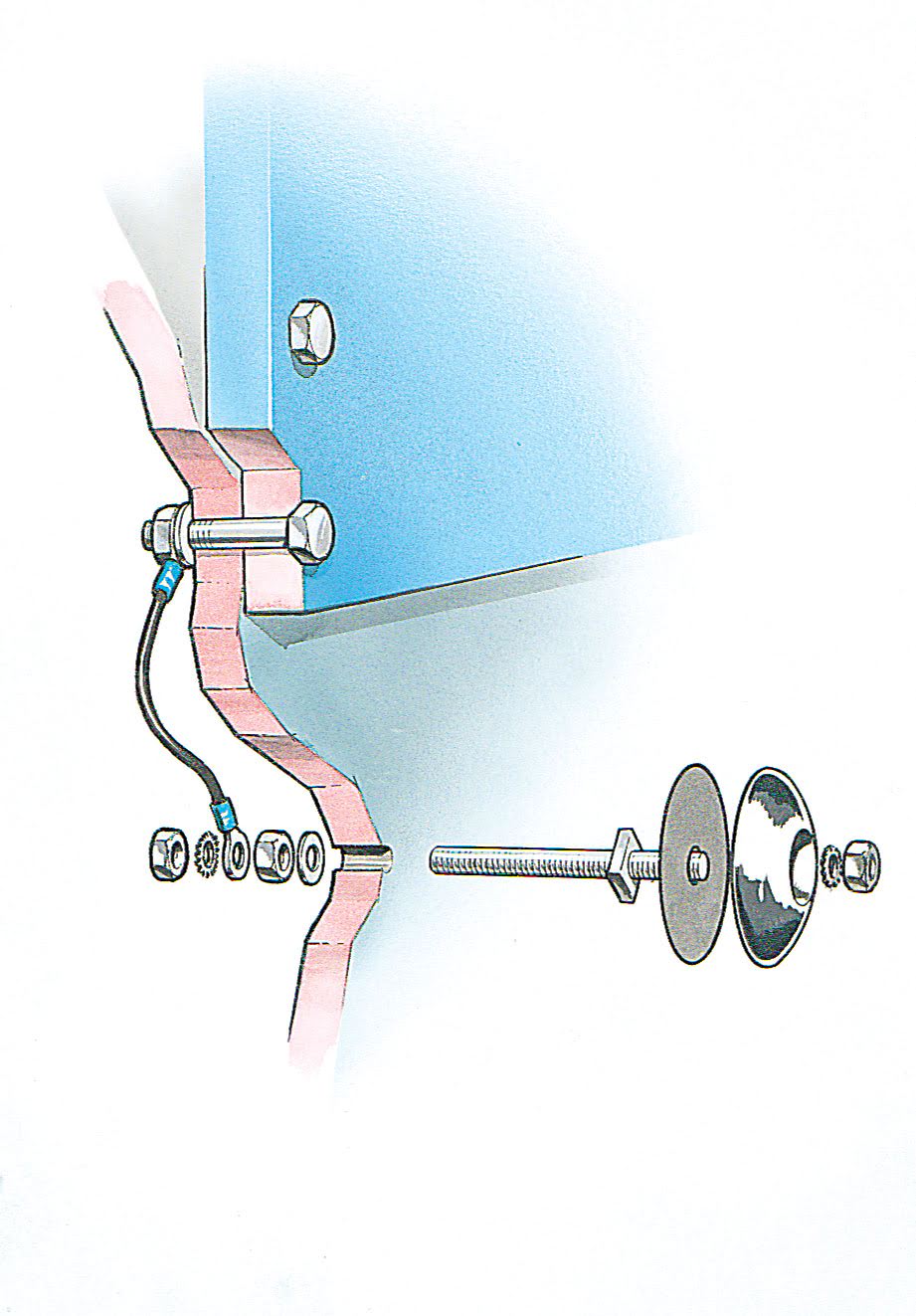

In these circumstances we recommend that a supplementary anode is fitted to the hull and bonded to the transom plate or drive flanges as shown:

In these circumstances we recommend that a supplementary anode is fitted to the hull and bonded to the transom plate or drive flanges as shown:

TYPE D - FOR EACH PROPELLER ASSEMBLY FIT ONE

| Propeller Diameter | In Salt Water | In Salt or Brackish Water | In Fresh Water |

|---|---|---|---|

| 250mm |

ZD56

Zinc Anode |

AD56

Aluminium Anode |

MD56

Magnesium Anode |

All schemes must be inspected annually and the anodes renewed if more than 50% wasted

Anode Placement

When fitting and replacing bolt-on anodes always ensure that the serrated fan disc washers are replaced

Related