Ferrocement Anode Fitting Instructions

Back

Fitting Instructions

This type of construction requires some special consideration but in principal we recommend that vessels of this type are treated in the same way as a GRP hull but with regard to the following:

As far as possible the hull steel reinforcement must be isolated from any metal work that is connected to the cathodic protection system. e.g. shaft brackets rudder bearings and glands as well as the anode itself.

It is unlikely that the hull steel reinforcement can be completely isolated and it will put some demand on the sacrificial anode. It is important to select a big enough anode to provide sufficient protection for this. We recommend that when selecting the correct anode for your boat you refer to knowledge base for further information on vessels in salt water and select the anode which is a size larger than that recommended for conventional GRP hulled vessels of the appropriate class.

Mild Steel Rudders, Skegs and Bilge Keels should be protected using the ZD58 Zinc Disc Anode.

As far as possible the hull steel reinforcement must be isolated from any metal work that is connected to the cathodic protection system. e.g. shaft brackets rudder bearings and glands as well as the anode itself.

It is unlikely that the hull steel reinforcement can be completely isolated and it will put some demand on the sacrificial anode. It is important to select a big enough anode to provide sufficient protection for this. We recommend that when selecting the correct anode for your boat you refer to knowledge base for further information on vessels in salt water and select the anode which is a size larger than that recommended for conventional GRP hulled vessels of the appropriate class.

Mild Steel Rudders, Skegs and Bilge Keels should be protected using the ZD58 Zinc Disc Anode.

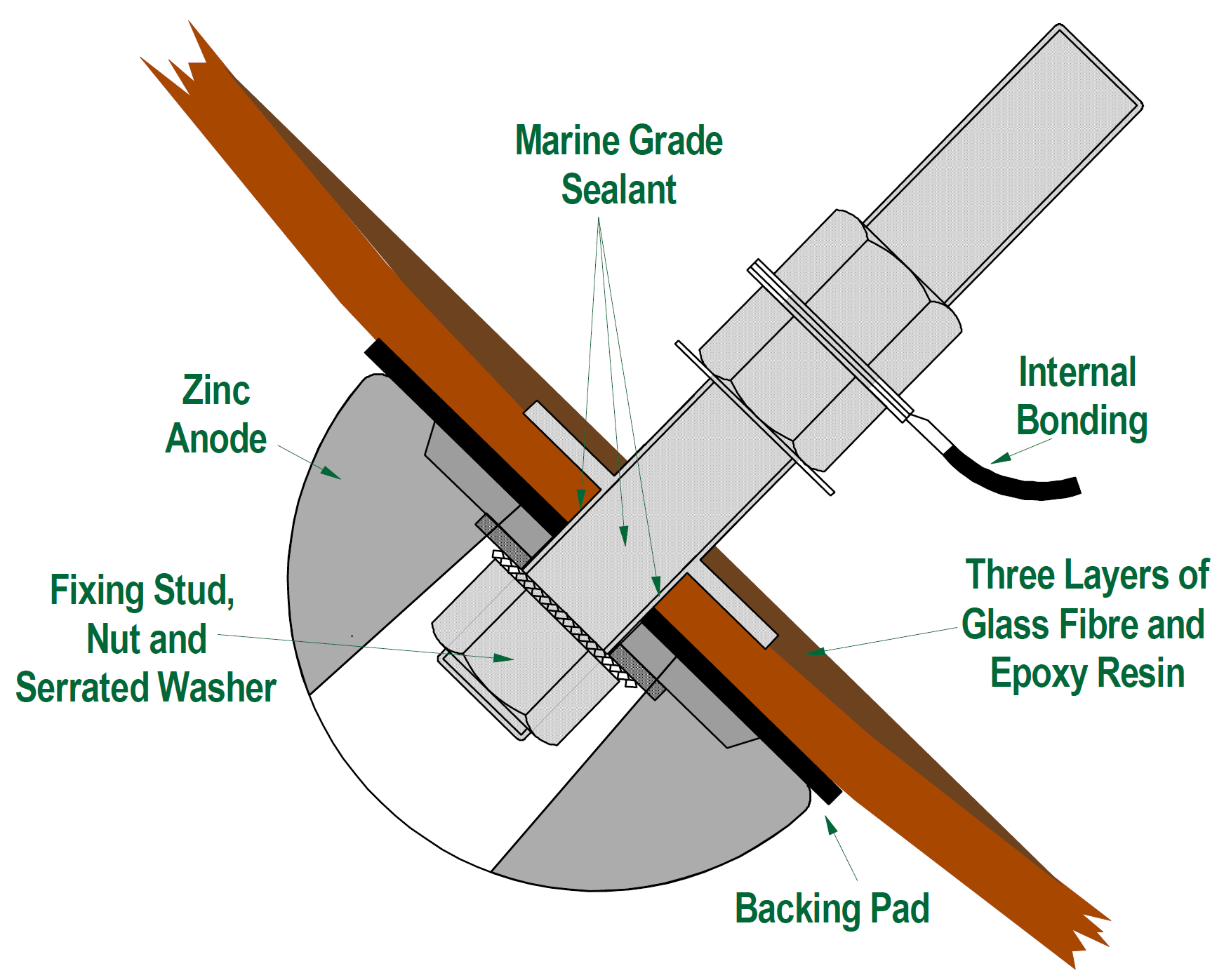

When installing the anode on a ferrocrete hull ensure that:

- The anode fixing studs are isolated from the hull steel reinforcement by fitting a plastic insulating sleeve to the shank of the stud and applying a generous amount of marine grade sealant.

- The anode fixing stud collar should be bedded in several layers of glass fibre and epoxy resin.

- The anode should be fitted with a rubberised foam backing pad.

- Always ensure that the anode is fastened with serrated washers under the fixing nuts to ensure a good connection.

- The anode should be bonded in accordance with the instructions for a GRP hulled vessel.