Wood & GRP Hull Anode Fitting Instructions

Back

Fitting Instructions

When fitting anodes to wooden or GRP hulled vessels remember:

- The anode must be position on the outside of the hull below the waterline.

- The anodes should “see” the parts to be protected.

- The fixing studs should be located above the bilges.

- The anode location ensures the minimum run of bonding cable to the parts to be protected.

- There must be reasonable internal access to the studs.

- The anode should not be positioned forward of or in line with Echo Sounding Transducers or log Impellers.

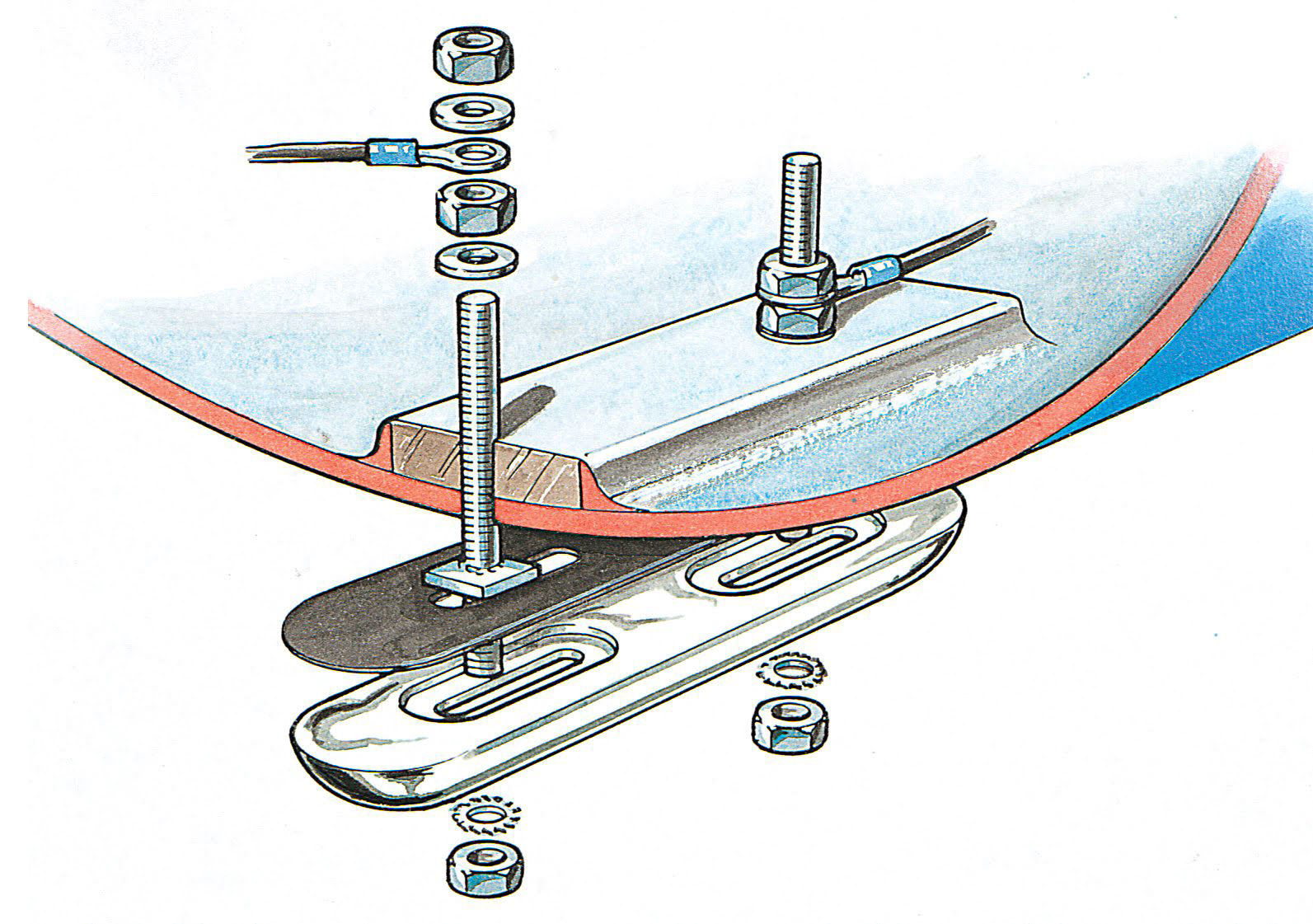

Stiffen the inside of the hull where the anode is to be fitted if necessary.

Drill holes to take the fixing studs at the appropriate centres.

On wooden hulled vessels studs should be sleeved or painted to insulate them from the surrounding timber. When sleeving the stud either use a heat shrink tube or ensure that the inside of the sleeve is packed with marine grade sealant.

Before inserting and securing each stud assembly, apply a generous amount of sealant to the shank and collar where the stud touches the hull to ensure a good seal.

Whenever an anode is fitted to a GRP or wooden hull an anode backing sheet must be used to control the wastage of the anode and protect the hull. The anode backing sheet should be replaced each time the anode is replaced.

Always ensure that the anodes are fitted with MGDUFF Fan Disc Washers under the securing nuts which will help to assure the contact between anode and cathodic protection system. The fan disc washers and nuts should be replaced each time the anode is replaced.

Protect the anode fixing studs on assembly with paint or grease inside and outside the vessel.

Drill holes to take the fixing studs at the appropriate centres.

On wooden hulled vessels studs should be sleeved or painted to insulate them from the surrounding timber. When sleeving the stud either use a heat shrink tube or ensure that the inside of the sleeve is packed with marine grade sealant.

Before inserting and securing each stud assembly, apply a generous amount of sealant to the shank and collar where the stud touches the hull to ensure a good seal.

Whenever an anode is fitted to a GRP or wooden hull an anode backing sheet must be used to control the wastage of the anode and protect the hull. The anode backing sheet should be replaced each time the anode is replaced.

Always ensure that the anodes are fitted with MGDUFF Fan Disc Washers under the securing nuts which will help to assure the contact between anode and cathodic protection system. The fan disc washers and nuts should be replaced each time the anode is replaced.

Protect the anode fixing studs on assembly with paint or grease inside and outside the vessel.

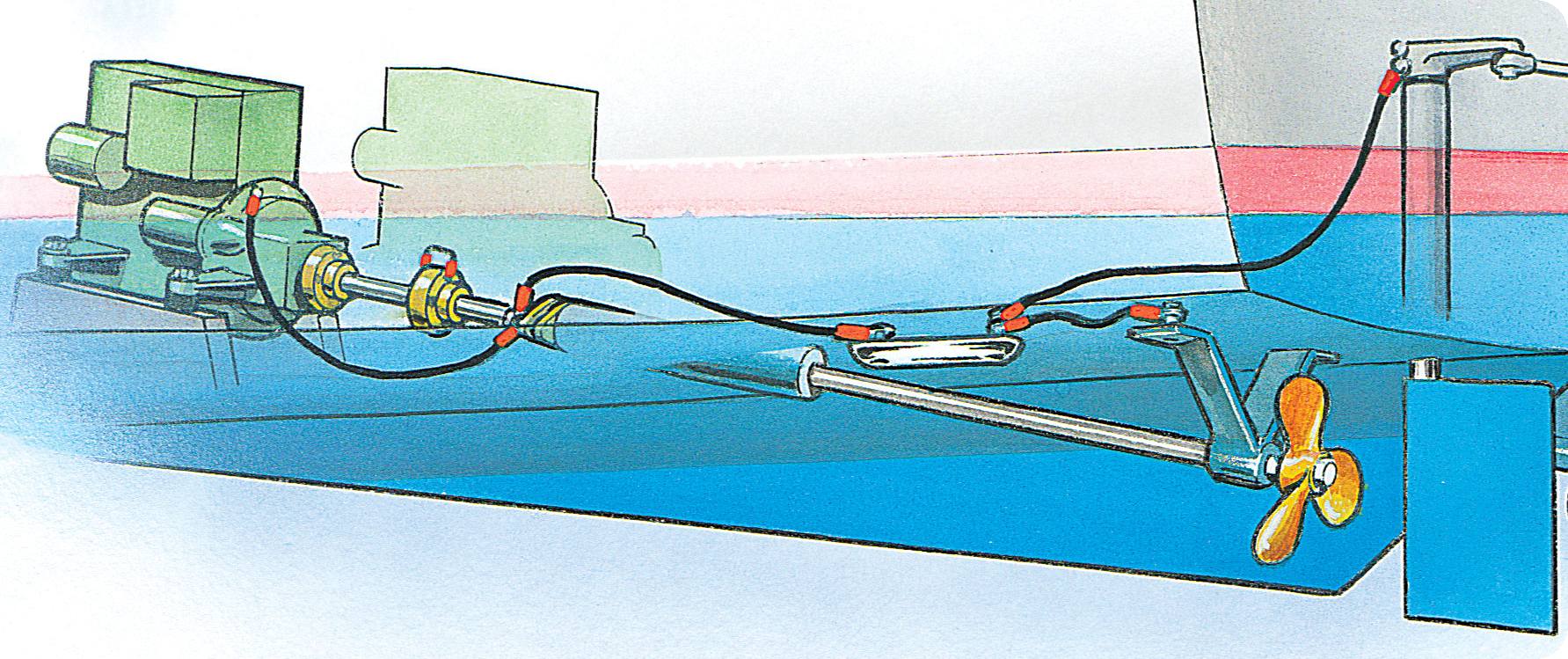

The correct bonding of the cathodic protection system is imperative.

Use 4mm2 PVC Insulated Multi-Stranded Single Core Copper Cable or larger.

Ensure that all connections are clean and tight.

The best way to bond the anode to the shaft is by using a MGDUFF Electro Eliminator as well as bonding the anode to the gear box or Engine casing.

Insulated Flexible Couplings should be bridged by using a short length of bonding cable or a copper strap to carry through the contact between anode shaft and propeller.

Bronze and Stainless Steel Rudders, Rudder Hangings and Shaft. Brackets should also be bonded to the main anodes.

Trim Tabs should be protected with separate anodes.

Do not bond the same anode to ferrous and non-ferrous metals or stainless steel. Steel Rudders must be protected with separate anodes.

Timber hulled vessels may be prone to electro-chemical decay and owners are recommended to contact MGDuff for specialist advice

Use 4mm2 PVC Insulated Multi-Stranded Single Core Copper Cable or larger.

Ensure that all connections are clean and tight.

The best way to bond the anode to the shaft is by using a MGDUFF Electro Eliminator as well as bonding the anode to the gear box or Engine casing.

Insulated Flexible Couplings should be bridged by using a short length of bonding cable or a copper strap to carry through the contact between anode shaft and propeller.

Bronze and Stainless Steel Rudders, Rudder Hangings and Shaft. Brackets should also be bonded to the main anodes.

Trim Tabs should be protected with separate anodes.

Do not bond the same anode to ferrous and non-ferrous metals or stainless steel. Steel Rudders must be protected with separate anodes.

Timber hulled vessels may be prone to electro-chemical decay and owners are recommended to contact MGDuff for specialist advice

Related